There are lots of opportunities for creativity with 3D printing, but not all projects are successful. Filament tolerance is something to consider. Both beginners and professionals must learn about the impact of filament tolerance on print quality in order to achieve strong, precise, and smooth prints. This guide details tolerance, how it impacts prints, and how to identify and repair connected issues.

What Is Filament Tolerance in 3D Printing?

Filament tolerance is the amount of variation in 3D printing filament thickness. It must be the same throughout the spool, but there can be slight variations when producing it. It is typically expressed in millimeters, such as ±0.05 mm.

Common Tolerance Ranges

- Standard Tolerance: Most PLA, ABS, and PETG filaments list a tolerance of ±0.05 mm. For a 1.75 mm filament, that means the actual size may range from 1.70 mm to 1.80 mm.

- High-Quality Filament: Premium brands may provide tighter tolerances, such as ±0.02 mm. This means the diameter remains between 1.73 mm and 1.77 mm, offering greater consistency.

Beginners should note that different filament materials not only have varying tolerance specifications but also unique printing requirements and end-use properties. Choosing the right type of filament for your skill level and project needs is just as important as understanding tolerance.

Tighter tolerance reduces variations in extrusion and lowers the risk of under- or over-extrusion problems.

How Filament Tolerance Affects Print Quality

The effect of filament tolerance on print quality is significant. The printer relies on precise control of extrusion, so even small diameter changes can create noticeable defects. Below are common issues caused by tolerance variation.

Under-Extrusion: When the Filament Is Too Thin

If the filament diameter is smaller than expected, the extruder feeds less material. This produces weak prints with visible gaps or missing lines. Common signs include:

- Poor layer adhesion and visible cracks.

- Thin walls that break easily.

- Brittle parts that lack durability.

Besides tolerance, under-extrusion may also result from clogged nozzles or incorrect temperature settings. If you see incomplete layers, start by checking filament diameter and nozzle health.

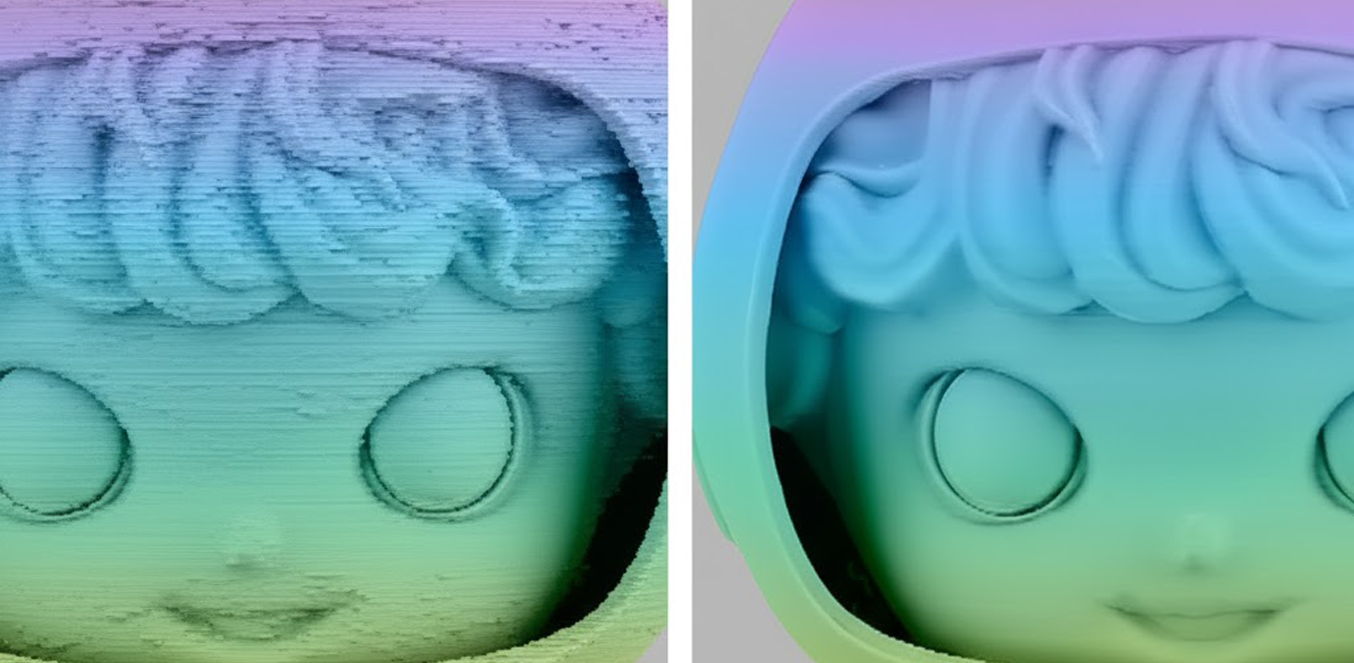

Over-Extrusion: Too Much Material, Loss of Precision

When the filament is thicker than expected, the printer pushes out too much plastic. This creates bulging surfaces and reduces dimensional accuracy. Symptoms include:

- Blobs or excess strings of plastic.

- Rounded corners and blurry details.

- Surfaces that feel uneven or rough.

While over-extrusion is often linked to tolerance, slicer settings such as flow rate or line width can make the problem worse.

Layer Separation: Weak Bonds Between Layers

Inconsistent extrusion can also weaken the bond between layers. When too little or too much plastic is deposited, adhesion suffers. The result is parts that peel apart under stress. To prevent this:

- Use filament with a tighter tolerance.

- Check that the layer height and extrusion multiplier match the nozzle size.

- Keep print speed steady to allow proper bonding.

Filament tolerance directly influences print strength, surface quality, and dimensional accuracy. Even small diameter variations can cause under-extrusion, over-extrusion, or weak layer bonding, making consistent filament essential for reliable results.

Identifying and Troubleshooting Filament Tolerance Problems

Filament tolerance issues can show up in many ways, from weak parts to rough surfaces. The key is to recognize the signs early and know how to respond. Below is a quick troubleshooting matrix, followed by step-by-step methods to identify problems more precisely.

Quick Troubleshooting Matrix

| Symptom | Likely Cause (Tolerance-Related) | Other Possible Causes | Quick Fixes |

| Gaps, brittle parts | Filament too thin (under-extrusion) | Partial clogs, low temp | Measure diameter, adjust flow, clear nozzle |

| Blobs, rough edges | Filament too thick (over-extrusion) | High flow, wide line width | Enter real diameter in slicer, lower flow |

| Layers split apart | Inconsistent extrusion | Low print temp, high fan | Tight tolerance filament, increase temp |

| Rough surfaces | Diameter fluctuation | Moisture, unstable temps | Dry filament, steady heat control |

| Stringing | Not always tolerance | High temp, poor retraction | Lower temp, adjust retraction |

This table gives a quick reference for matching common print defects to possible causes. In practice, tolerance is just one factor, but checking it early helps rule out material inconsistency before diving into printer settings.

3 Proven Methods to Identify Filament Tolerance Problems

- Inspect Your Prints Closely: Inspect your prints closely. Bubbles, lumps, hard corners, or rough patches typically indicate that there are defects in the material. You can typically spot these defects by visual examination alone.

- Filament Thickness Measurement: Check the thickness of the filament at various locations on the spool with a digital caliper. Each time, rotate the filament 90° to check if it is oval or round. A typical 1.75 mm filament measuring between 1.70 and a smidge over 1.80 mm can lead to major extrusion issues.

- Print Quality Inspection: If the layers are detaching frequently, the parts are not strong, or the same issues are on the print surface, the filament is likely of poor quality. You can make minor alterations by tweaking slicer settings, but if issues continue to occur in prints, the spool of filament is likely of poor quality.

Filament tolerance may seem minor, but it often decides whether prints come out strong or fail. With a quick visual check, diameter measurements, and watching print behavior, you can spot tolerance issues early. This makes it easier to fine-tune slicer settings or switch spools, saving both time and material. Understanding tolerance is just one of many strategies that can significantly reduce your overall print failure rate.

Choosing the Right Filament for Consistent Quality

The consistency of filament tolerance largely depends on how well it is manufactured. Selecting high-quality filament not only improves print reliability but also saves time spent on troubleshooting.

Brand and Quality Control

Trusted brands usually enforce tighter quality standards and may even provide laser-measured data for each production batch. While these spools often cost more, they reduce variation, improve extrusion stability, and deliver smoother, more accurate prints.

Printer Compatibility

Different printers respond differently to tolerance variations. Printers with fine nozzles (0.2–0.4 mm) demand stricter tolerance to avoid under- or over-extrusion, while machines using larger nozzles can often handle ±0.05 mm without serious issues. Matching the filament to your printer's requirements ensures consistent performance.

Proper Storage

Even the best filament can print poorly if not stored correctly. Over time, filament absorbs moisture from the air, leading to popping noises, weak adhesion, or rough surfaces. Moisture absorption can cause filament to swell and change diameter, directly contributing to tolerance-related issues. Additionally, moisture creates printing defects like bubbling and poor layer adhesion that compound tolerance problems. Keeping spools in airtight containers with desiccants helps preserve quality and prevents wasted prints.

Unlock Reliable 3D Printing

A small change in filament tolerance can mean the difference between a flawless print and a failed one. By keeping an eye on your prints, measuring your filament, and catching issues early, you stay in control of quality. With the right filament and good storage habits, every project has a better chance of coming out strong, smooth, and reliable.