3D printing brings creativity, but it also creates waste—failed prints, supports, rafts, and empty spools pile up fast. Many wonder if this plastic can really be recycled.

Most filaments can be melted again, but challenges make it tricky:

- Different materials need different conditions.

- Small scraps are hard to process in batches.

- Dust or color mixing lowers quality.

Recycling works best through home setups or local programs, starting with knowing how each material behaves.

How to Prevent 3D Printing Waste Before It Starts

The most reliable way to keep plastic out of landfills is not recycling—it's preventing waste in the first place. Careful preparation ensures more successful prints and fewer discarded models or oversized supports.

Design and Slicing Choices

- Orient models to reduce the need for support structures.

- Incorporate chamfers, fillets, or bridges where possible.

- Try tree supports or interface layers for cleaner removal.

- Break large objects into smaller sections that fit the build plate more efficiently.

Printer Setup

- Run temperature calibration tests to determine the ideal extrusion point.

- Keep filament sealed in airtight containers with desiccants.

- Regularly check bed leveling and adhesion to prevent warping.

Smart Printing Habits

- Start with small test prints before committing to long jobs.

- Monitor prints with cameras or sensors to catch problems early.

- Use adaptive layer heights to balance surface quality with speed.

Thoughtful design choices, accurate calibration, and careful oversight save more plastic than recycling efforts alone ever could.

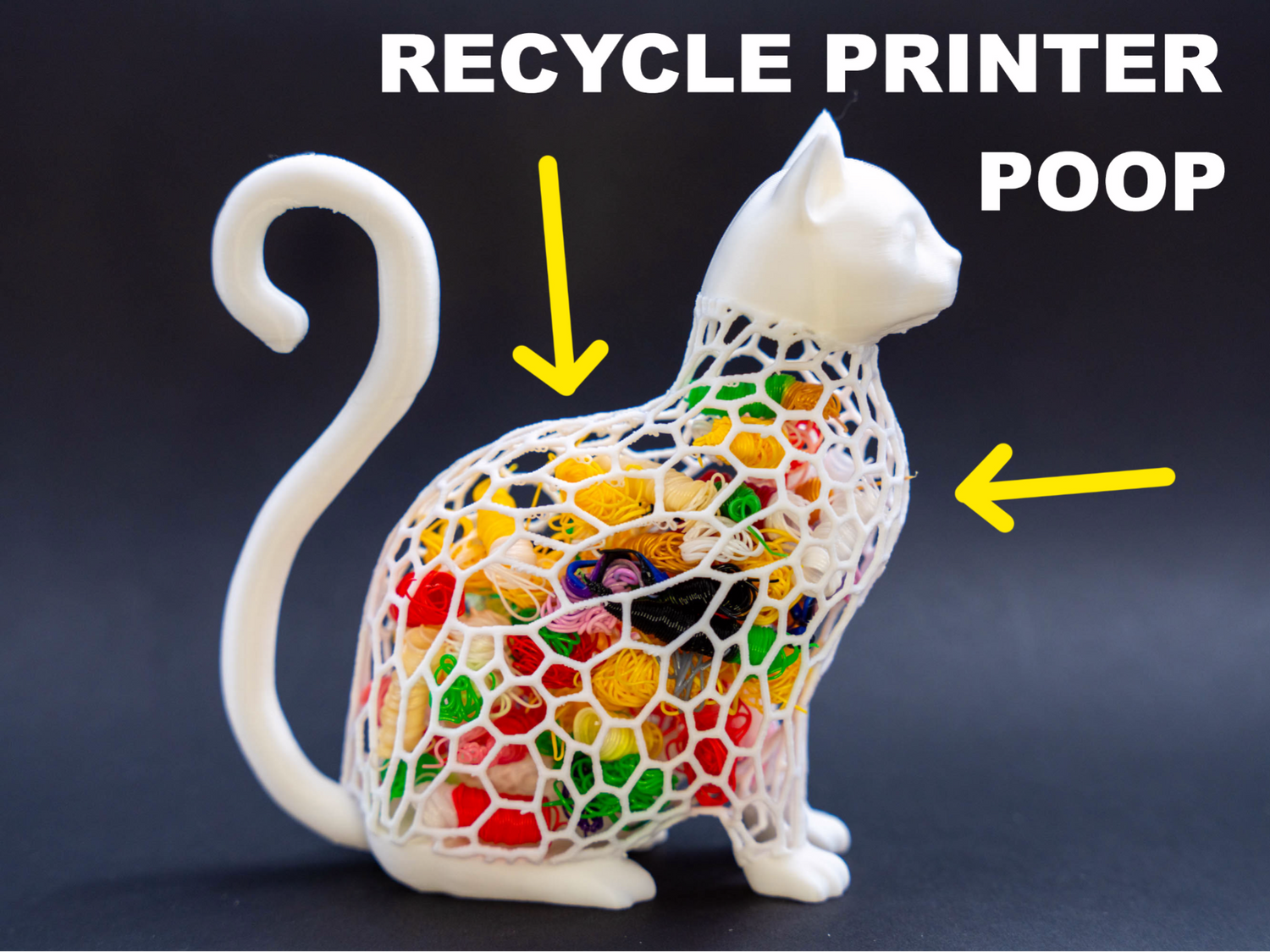

Creative Reuse of Failed Prints and Scraps

Not every failed print has to be ground down and re-extruded. Many pieces can be reused directly for practical or creative applications.

Simple Reuse Ideas

- Home utility: Convert failed parts into key holders, wall hooks, or garden labels.

- Workshop aids: Repurpose scraps as spacers, clamps, or protective pads.

- Art projects: Assemble fragments into mosaic-style panels or mixed-media works.

- Education: Provide samples for sanding, painting, or practicing assembly in classrooms.

Repair and Maintenance

- Use a 3D pen with leftover filament to fill cracks or patch gaps.

- Weld softened fragments together for reinforcement.

- Mix shavings or flakes with epoxy to create textured or decorative surfaces.

Reusing scraps transforms waste into value without the complexity of extrusion.

Recycling 3D Printer Filament at Home

For makers willing to invest in equipment, home recycling offers a way to turn waste back into usable filament. It requires patience and close attention to detail, but it is achievable.

Basic Workflow

- Sort by material: Keep PLA, ABS, PETG, nylon, and TPU separate.

- Clean and dry: Remove dust and moisture to avoid bubbling.

- Shred or cut: Break failed prints into small, manageable pieces.

- Extrude: Feed scraps into a filament extruder and wind onto spools.

- Test: Measure diameter consistency before committing to large projects.

Key Equipment

- A reliable shredder or heavy-duty grinder.

- A small-scale filament extruder with a winding mechanism.

- A temperature-controlled dryer or oven for moisture-sensitive plastics.

- Protective gear and good ventilation, especially when handling ABS or nylon.

Practical Limits

- Each reheating cycle slightly weakens polymer chains, reducing strength.

- Mixed colors or additives often result in uneven output.

- Achieving ±0.05 mm diameter tolerance requires precise equipment.

Home recycling works best for enthusiasts who enjoy experimentation and are comfortable with variable outcomes. To make the process more efficient and organized, many makers set up a small recycling station at home.

Setting Up a Simple Home Recycling Station

Organization is the backbone of any recycling effort. A dedicated station keeps tools and scraps in order, making recycling smoother and preventing contamination.

| Item | Function | Notes |

| Labeled bins | Separate scraps by polymer | Keeps materials clean and reusable |

| Dryer or oven | Remove moisture | Critical for PETG and nylon |

| Cutting tools | Prepare pieces for extrusion | Use gloves for safety |

| Work surface | Safe prep area | Non-slip mats protect furniture |

| Safety gear | Dust and fume protection | Goggles, masks, and extinguisher recommended |

Even a modest setup can make sustainable practices part of everyday printing. And for those who prefer not to invest in home solutions, community recycling options remain available.

Special Handling for PLA and Water-Soluble Supports

Not every filament behaves the same at the end of its life, and two common materials—PLA and water-soluble supports—need extra attention.

PLA

PLA is marketed as biodegradable, but this label is misleading. True breakdown happens only in industrial composting facilities that maintain controlled temperatures of about 135 °F (58 °C) with regulated moisture and microbial activity. In a household compost bin, PLA can remain intact for years with little visible change.

Water-Soluble Supports

Materials like PVA or BVOH dissolve in water, but disposal requires care. Pouring concentrated solutions directly into drains may strain wastewater treatment systems. A safer approach is to dissolve supports in small batches, filter out solids, and dilute the liquid before releasing it into household wastewater—never storm drains. Understanding these differences ensures waste is handled safely and responsibly. Beyond filaments themselves, there are also accessory items and fine particles that need to be managed properly.

Other Waste: Spools, Packaging, and Dust

Filament waste extends beyond printed parts. Accessories and micro-particles also require proper handling.

- Empty spools: Repurpose them as storage reels, organizers, or stands. Some hobbyists even use them for cable management.

- Vacuum bags and desiccants: Save and reuse for partially used spools; regenerate desiccants with gentle heat.

- Dust and sanding waste: Wet-sand to control airborne particles, let slurry settle, and bag residue. Use a HEPA vacuum for drilling or cutting tasks.

Paying attention to these small details completes a responsible recycling routine and helps reduce microplastic release. With accessories and special materials addressed, the next step is deciding whether to manage waste at home or turn to community solutions.

External Recycling and Local Options

Not everyone has the time or desire to recycle at home, but local opportunities still exist.

- Makerspaces and schools often collect scraps for group recycling or research.

- Municipal recycling centers may accept sorted thermoplastics in small batches.

- Community art groups sometimes repurpose filament waste into creative projects or furniture.

Before dropping off scraps, always confirm what materials are accepted, whether cleaning is required, and how they prefer items packaged. Local collaboration provides convenient outlets for otherwise wasted material and offers a community-driven way to support sustainability.

Small Recycling Habits Make a Big Difference

You don't have to change much to see an impact. Just one mishap a week—about 100 grams of wasted filament—adds up to more than 5 kilograms (11 pounds) of plastic each year. Cut that waste in half by making fewer errors, reusing scraps, or recycling, and the benefits are clear both for the environment and for your wallet. Eco-friendly 3D printing isn't about perfection but about consistent habits. Whether it's sorting scraps, keeping spools in use, or experimenting with recycled filament, every small step adds up. Together, makers can reduce waste while keeping the joy of printing alive.

FAQs

Q1: Does acetone smoothing work for PLA prints?

No. Acetone vapor smoothing works with ABS and ASA because it softens their surfaces, but PLA does not react the same way. Applying acetone to PLA often causes cracks or weakens the part. Safer finishing options for PLA include sanding, priming, or using solvents like ethyl acetate.

Q2: Is it safe to flush water-soluble supports directly down the drain?

Not in large amounts. PVA and BVOH dissolve quickly, but dumping concentrated solutions can stress wastewater systems. Dissolve supports in small batches, strain and dilute the solution, and only pour into domestic drains—never storm drains.

Q3: Can different polymers and colors be mixed together for recycling?

No. Grinding polymers such as PLA, ABS, and PETG together produces weak, inconsistent filament because of their different bonding and melting properties. Mixed dyes also tend to result in muddy, unattractive colors. For reliable print quality, always keep scraps separated by polymer type and, ideally, by color.