Your choice between PLA and PETG should always start with what the final part needs to do. For prints that are purely visual, PLA is often the best answer. It’s simple to print and captures fine details beautifully. However, if a part must be strong, resist heat, or bend without breaking, you need the durability of PETG. This guide lays out their core differences and printing needs to make that choice clear and simple.

PETG vs PLA Filament: Head-to-Head Comparison of Core Properties

At a glance, the differences between PLA and PETG are stark. One prioritizes ease and rigidity, while the other champions durability and resistance. This table breaks down their primary characteristics, showing a clear winner for each category based on performance.

Properties Overview Table

| Property | PLA (Polylactic Acid) | PETG (Polyethylene Terephthalate Glycol) | Winner For... |

| Strength & Durability | Stiff and rigid, but brittle. Prone to snapping under stress. | More flexible, less rigid. Excellent impact resistance and ductility. Bends before it breaks. | PETG (Durability) |

| Temperature Resistance | Low (~60°C). Deforms in a hot car or direct sunlight. | High (~80°C). Much more stable in higher-temperature environments. | PETG |

| UV Resistance | Poor. Becomes more brittle and can discolor with sun exposure. | Good. Suitable for outdoor applications. | PETG |

| Chemical Resistance | Limited. Susceptible to many common solvents. | Excellent. Resistant to salts, acids, bases, and many solvents. | PETG |

| Ease of Use | Very easy. Forgiving, minimal warping, less stringing. | Moderate. Prone to stringing/oozing. Requires more careful tuning. | PLA |

| Food Safety | Generally considered food-safe in its raw form. | Generally considered food-safe in its raw form. | Tie (with a major caveat) |

| Post-Processing | Easy to sand and paint. Can be glued with superglue. | More difficult to sand (can "gum up"). Can be painted but may require primer. | PLA |

| Hygroscopicity | Low. Absorbs moisture from the air slowly. | High. Absorbs moisture quickly, which severely degrades print quality. | PLA (Easier Storage) |

Key Properties Explained

1. Strength & Durability: Rigidity vs. Toughness

When we talk about 3D printing materials, "strength" can mean a couple of different things.

PLA is like uncooked spaghetti. It's very stiff and holds its shape perfectly, which is great for things like detailed models or figurines. But if you try to bend it, it doesn't give—it just snaps. So, while it's rigid, it's also quite brittle.

PETG is more like a tough plastic container. It has some flex to it. If you put it under pressure, it will bend before it breaks. This makes it much more durable and a better choice for mechanical parts, or anything that might get dropped or squeezed.

2. Temperature and UV Resistance: The Deciding Factor for Applications

PLA gets soft in the heat. If you leave a PLA print in a hot car, you'll come back to a warped, droopy mess. It also doesn't like the sun and can get brittle and change color over time.

PETG can handle the heat much better. It's the clear winner for anything you plan to use outdoors or in a hot environment, like a phone holder for your car's dashboard.

3. Hygroscopicity: Why Proper Storage is Critical

PETG is like a sponge for moisture in the air. If it absorbs too much, the water turns to steam in the hot nozzle of your printer. This causes popping sounds, leaves ugly strings all over your print, and makes the final part weak and foamy. It's super important to store PETG in a dry place.

PLA is much more chill about moisture. You can leave it out in a room for a while and it will usually be fine. It's a lot more forgiving and easier to store.

4. Critical Reminder: The Truth About "Food Safety"

Even though the raw plastic pellets for both PLA and PETG are considered food-safe, the 3D printing process changes things. The tiny lines between the layers of a print are a perfect hiding spot for bacteria and are almost impossible to get completely clean. Also, some printer nozzles are made of brass that can contain a small amount of lead, which you definitely don't want in your food.

PETG vs PLA Filament: Printing and Settings

Printing successfully with PETG requires different slicer settings than PLA. Failing to adjust for its unique properties often leads to stringing and weak parts. This guide covers the essential settings you'll need to change.

Setting Nozzle and Bed Temperatures

PETG requires significantly higher temperatures than PLA to print correctly.

- PLA: Prints at lower temperatures (Nozzle: 190-220°C; Bed: 20-60°C or unheated).

- PETG: Needs more heat for proper flow and layer bonding (Nozzle: 230-250°C; Bed: 70-85°C). A hot bed is crucial to prevent the print from warping.

Preventing Over-adhesion and Damage

While PLA adheres well to most surfaces, PETG can stick too well, creating a serious risk of damaging your build plate.

Critical Warning: PETG can bond so strongly to glass or PEI surfaces that it can rip chunks from the build plate when a print is removed. To prevent this, always use a release agent like a glue stick or hairspray as a barrier between the print and the bed.

Controlling the Part Cooling Fan

The two materials require opposite approaches to part cooling.

- PLA: Requires high fan speeds (typically 100%) to cool quickly, which produces sharper details and cleaner bridges.

- PETG: Needs less cooling (20-50% fan speed). Too much fan can weaken the bonds between layers, leading to brittle parts.

Combating Stringing and Oozing

Stringing is the biggest challenge when printing with PETG. Its viscous nature causes it to drip from the nozzle during travel moves, leaving fine plastic strings.

To fix this:

- Tune Retraction: Increase both the retraction distance and speed to pull filament back more effectively.

- Increase Travel Speed: Faster movements between printed areas give the filament less time to ooze.

- Enable Coasting: This slicer feature stops extruding just before a travel move, relieving nozzle pressure.

- Ensure Filament is Dry: As noted earlier, wet PETG is a primary cause of excessive stringing.

Keeping Filament Dry

The two materials have very different needs for storage due to how they absorb moisture.

- PLA: Is not very hygroscopic and is forgiving if left in a typical room for short periods.

- PETG: Is highly hygroscopic and absorbs moisture like a sponge. Printing with "wet" PETG causes popping sounds, severe stringing, and weak, foamy parts. It is essential to store PETG in a sealed container with desiccant or use a dedicated filament dryer to restore a wet spool.

PETG vs PLA Filament: Use Cases & Examples

The choice between PLA and PETG becomes simple when you consider the intended purpose of your print.

When to Choose PLA: For Detail and Ease of Use

Choose PLA when your priority is aesthetic quality and ease of printing over mechanical performance.

- Visual Prototypes: For quick, inexpensive mockups where the look and feel are more important than function, PLA is the fastest and easiest material to use.

- Models & Figurines: Because PLA captures fine detail so well and is easy to sand and paint, it's perfect for intricate statues, miniatures, and display pieces.

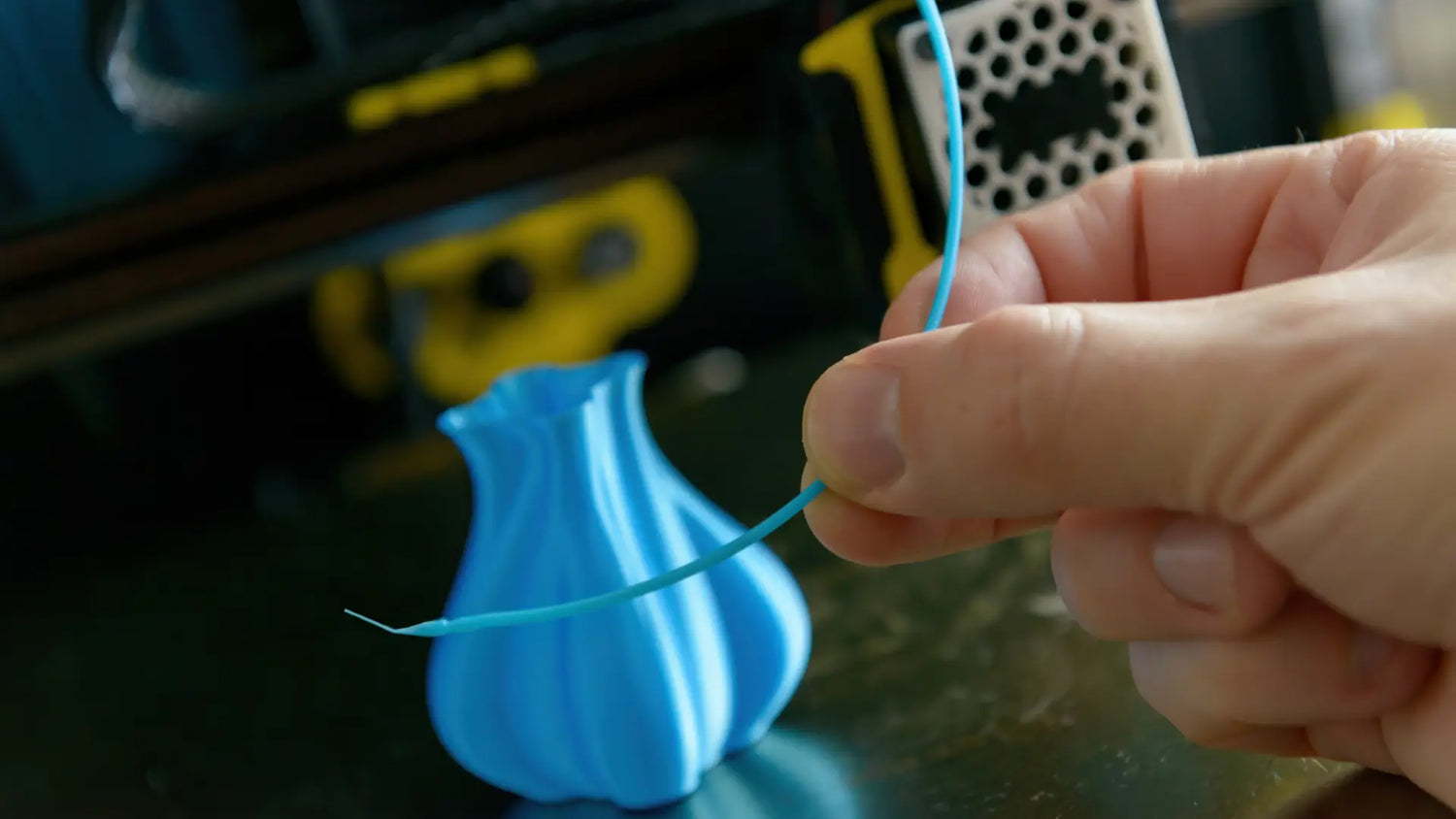

- Low-Stress Items: Objects that won't be dropped, stressed, or exposed to heat are perfect for PLA. This includes decorative vases, desk organizers, and many children's toys.

- Beginner Projects: For those new to 3D printing, PLA is the ideal starting material. Its forgiving nature allows you to build foundational skills with minimal frustration.

When to Choose PETG: For Strength and Durability

Turn to PETG when your project needs to survive in the real world, enduring stress, weather, or heat.

- Functional & Mechanical Parts: With its high strength and flexibility, PETG is the go-to material for parts that work, like mounting brackets, simple gears, tool holders, and protective cases for electronics.

- Outdoor Items: Excellent UV and weather resistance means PETG won't become brittle or discolor in the sun, making it ideal for custom planters, garden tools, or components for drones and RC cars.

- Items for High-Temp Environments: A part printed in PLA will warp into a sad puddle if left in a car on a summer day. PETG's higher temperature resistance allows it to be used for objects like a custom phone mount for your car's dashboard.

- Snap-Fit Enclosures: The slight flex of PETG is a significant advantage for creating enclosures or containers with lids that need to snap securely into place without breaking the tabs.

Arm Your Printer with the Right Material!

There is no universal "best" 3D printer filament. The superior material is the one that directly matches the demands of your specific application. A well-rounded 3D printing practitioner knows how to leverage the distinct advantages of both. Use PLA when you require beautiful models, rapid prototypes, and a frictionless printing experience. Call upon PETG when your project demands parts that are strong, tough, and built to last. By aligning the material to the mission, you ensure every print is a success.