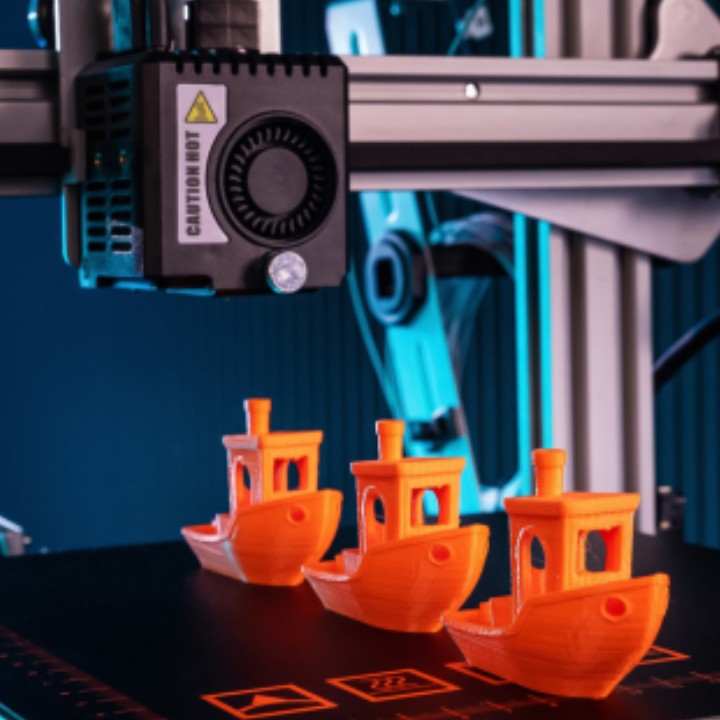

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital model by layering materials one on top of the other. It allows for the creation of complex geometries and shapes that would be difficult or impossible to achieve with traditional manufacturing techniques.

How 3D printing works

The basic process of 3D printing involves several steps:

Design: The first step in 3D printing is to create a digital model of the object you want to print using computer-aided design (CAD) software. The model is then exported as an STL file, which is a standard file format used for 3D printing.

Slicing: The next step is to prepare the STL file for printing by slicing it into thin layers using slicing software. The slicing software determines the optimal path for the printer's nozzle to follow as it deposits material layer by layer.

Printing: Once the file is sliced, it is loaded into the 3D printer, and the printing process begins. The printer's nozzle deposits material layer by layer, building up the object from the bottom up. The material used can vary depending on the printer's technology and the object being printed, but common materials include plastics, metals, and ceramics.

Finishing: After the object is printed, it may require post-processing to remove any support structures or excess material. Some objects may also require additional finishing, such as sanding or painting.

There are several different types of 3D printing technologies, each with its own advantages and disadvantages. Some of the most common 3D printing technologies include fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). Each technology uses a different method for depositing and curing the printing material, but the basic process of designing a digital model, slicing it into layers, and printing it layer by layer remains the same.

Advantages and disadvantages of common 3D printing technologies

Fused Deposition Modeling (FDM)

Advantages:

Widely available and affordable

Can print with a variety of materials, including PLA, ABS, and nylon

Easy to use and maintain

Disadvantages:

Limited resolution and accuracy

Poor surface finish

Limited ability to print complex geometries

Stereolithography (SLA)

Advantages:

High precision and accuracy

Can print with a variety of materials, including high-performance resins

Smooth surface finish

Disadvantages:

Expensive compared to FDM

Limited build volume

Requires post-processing to remove excess resin and cure the final object

Selective Laser Sintering (SLS)

Advantages:

Can print with a wide range of materials, including metals and ceramics

High resolution and accuracy

No need for support structures

Disadvantages:

Expensive compared to FDM and SLA

Limited availability of machines and materials

Requires post-processing to remove excess powder and sinter the final object

Digital Light Processing (DLP)

Advantages:

High resolution and accuracy

Fast printing speed

Can print with a range of materials, including high-performance resins

Disadvantages:

Expensive compared to FDM

Limited build volume

Requires post-processing to remove excess resin and cure the final object

Overall, the choice of 3D printing technology depends on the specific requirements of the project, including the desired resolution, accuracy, material properties, and cost. Each technology has its own strengths and weaknesses, and it's important to consider these factors when selecting a 3D printing technology for a particular project.