Silk PLA filament creates glossy prints that stand out, but only when handled with care. Compared to standard PLA, it brings extra challenges. Below, we’ll walk through typical silk PLA printing issues—grouped logically—so you can fine-tune your setup with fewer headaches.

1. How to Fix Silk PLA First Layer Not Sticking

If your print lifts at the corners or the first layer doesn’t bond well, silk PLA’s smooth texture might be the reason. Many failed prints start with poor first-layer adhesion. The filament’s slipperiness and slightly altered flow can lead to problems if your setup is even slightly off.

Why it happens:

Bed leveling may be off, or your nozzle may sit too far above the surface. Silk PLA also requires slightly higher bed temperatures, and an unclean surface can further reduce grip.

What to do:

- Re-level the bed carefully and adjust Z-offset.

- Increase bed temperature to 60–65°C.

- Slow down the first layer to below 20 mm/s.

- Clean the print bed and apply glue stick or use a PEI surface (note: smooth PEI may need glue for silk PLA to grip reliably).

- Consider printing a skirt or brim to help prime extrusion and improve edge bonding.

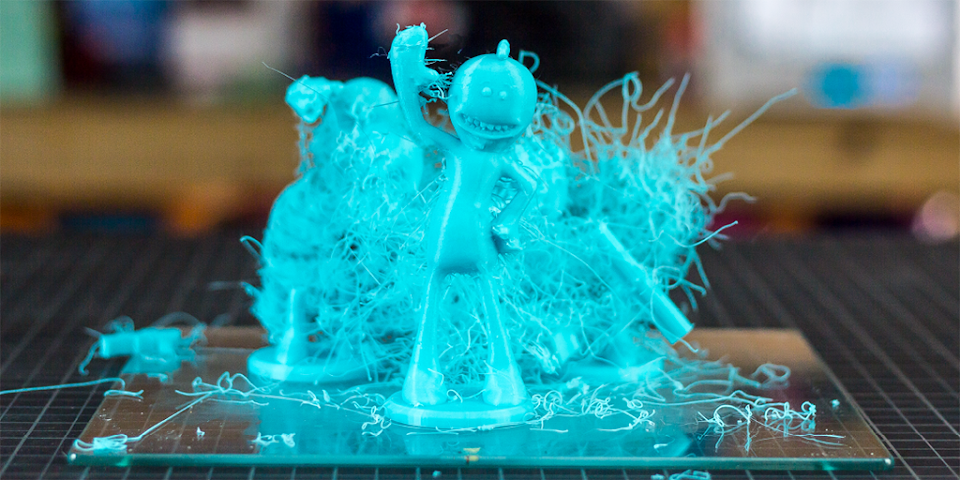

2. How to Reduce Stringing and Blobs in Silk PLA Prints

Fine stringing or blobs on surfaces are especially noticeable on shiny silk PLA prints. These problems often occur between separate features of a model, such as posts or towers, and can make an otherwise smooth surface look messy.

Why it happens:

Printing too hot or using weak retraction settings encourages oozing. Excess pressure and seam buildup can leave visible marks. If the filament is slightly wet, it can even sizzle and bubble as it extrudes, creating random specks or fuzz.

What to do:

- Drop nozzle temp to 200–215°C, adjusting for your specific brand.

- Use proper retraction distance and speed: 1–2mm for direct, 4–6mm for Bowden.

- Enable coasting and randomize seam positions.

- Dry filament thoroughly before printing.

- Try lowering travel speed or enabling combing mode to reduce unnecessary movement.

3. How to Improve Overhangs and Bridges When Printing with Silk PLA

Bridge sag and overhang deformation often appear in silk PLA due to its slower cooling behavior. Because the filament stays soft longer, unsupported features can droop before hardening.

What to check:

- Is your fan speed high enough?

- Are you using supports where needed?

- Are you printing bridges at too high a speed?

How to improve:

- Increase fan speed to 100% after the first few layers.

- Lower the temperature slightly.

- Add support structures for overhangs steeper than 50–60°.

- Slow down the bridge print speed in your slicer.

- Avoid printing long bridges without reinforcement—break large spans into supported segments if possible.

4. How to Avoid Cracks and Strengthen Layer Bonding in Silk PLA

Parts snapping or delaminating midway often indicate poor bonding or thermal stress. This is especially frustrating in tall vases or thin vertical walls, where failure can occur late in the print.

Why it happens:

Low print temps, aggressive cooling, and improper orientation make vertical prints vulnerable. A cold room or an overpowered fan can quickly cause cracking between layers.

How to fix it:

- Raise nozzle temp to 210–215°C.

- Lower cooling fan to 50–70% after the first few layers.

- Slow down print speed to 30–45 mm/s.

- Print in a warmer room or use an enclosure.

- Reorient thin structures to improve strength.

- Increase the number of walls and infill percentage to reinforce vertical shapes.

5. How to Fix Under-Extrusion and Flow Issues in Silk PLA Printing

If your print has gaps, missing lines, or brittle infill, extrusion may be inconsistent. The shiny finish of silk PLA tends to make these flaws more noticeable, even on otherwise small details.

Possible causes:

Partial clogs, low flow rate, worn nozzles, or wet filament. A filament diameter that fluctuates slightly can also throw off fine-tuned settings.

What to do:

- Some users find that a 0.5mm+ nozzle allows silk PLA to flow more smoothly, but 0.4mm nozzles can also perform well when calibrated.

- Recalibrate E-steps and verify flow rate.

- Dry filament before use.

- Replace worn brass nozzles or upgrade to hardened steel.

- Watch the first few layers closely—early under-extrusion often predicts bigger problems later.

6. How to Get a Smooth Finish and Eliminate Banding in Silk PLA

Silk PLA’s reflective surface highlights even minor imperfections in movement or layer consistency. Banding or uneven sheen can appear across flat or gently curved surfaces, distorting the final look.

Root causes:

Z-axis wobble, mechanical vibration, or extrusion instability. Even environmental factors like table shake or loose belts can result in subtle line shifts.

What helps:

- Reduce print speed to minimize shaking.

- Clean and align Z-rods or lead screws (for printers with alternative Z mechanics, follow the device-specific maintenance guide).

- Use ironing or light sanding to improve surface uniformity.

- Tighten belts and secure your printer on a sturdy surface.

- Print two at a time to give layers more cooling time and reduce shine banding.

7. How to Prevent Heat Creep and Nozzle Damage When Using Silk PLA

Filament stops extruding halfway, or the nozzle jams? These are signs of thermal creep or wear. Silk PLA’s additives can soften prematurely and cling to internal hotend walls.

Heat creep symptoms:

Filament softens too early inside the hotend, especially during slow prints. You might notice that extrusion slows down or stops altogether in the middle of a job.

Nozzle wear signs:

Rough extrusion, inconsistent layer width, or more stringing than usual. The wear is gradual and can go unnoticed until prints degrade noticeably.

Solutions:

- Upgrade to an all-metal hotend with proper heat dissipation.

- Keep the heatsink fan running full speed.

- Avoid long pauses or extremely slow speeds.

- Use hardened nozzles for long-term use with silk PLA.

- Check extrusion width visually during the print—any unevenness may signal early wear.

[[related_products_1]]

The Silk PLA Payoff: Worth the Extra Care

With silk PLA filament, visual payoff comes with extra setup care. Pay attention to temperature, retraction, and cooling. Once tuned, this filament delivers results that look polished straight off the bed. Don’t expect perfect results immediately—each printer and spool behaves slightly differently. But with the tips above, you’ll have a reliable process to troubleshoot common issues. Give your settings a few tweaks, and your silk PLA prints will soon shine—literally.