It's important to take out plastic the right way. If you do it carefully, your prints will look better and your printer will last longer. But if you do it the wrong way, you can cause a lot of problems and waste time.

This guide will show you the right steps to unload plastic. It also has tips for fixing problems and advice on how to store your plastic. This is so changing the plastic spools is easy for you. For those new to the hobby, learning what kind of filament is more suitable can make the entire process much smoother.

Heating the Nozzle to Prepare for Smooth Filament Removal

You must heat the nozzle before taking the filament out. You do this because heating makes the plastic soft inside. So, it's much easier to pull out, and you won't break the printer or the plastic. Different types of plastic need different heat levels to soften. So, it's very important to know the right temperature for the kind of plastic you are using.

Recommended Nozzle Temperatures for Common Filaments

| Filament Type | Temperature Range (°C) | Notes |

| PLA | 190 - 210 | Softens easily, good for beginners |

| ABS | 230 - 250 | Requires higher heat to avoid warping |

| Nylon | 250 - 270 | Absorbs moisture easily, needs dry storage |

| TPU | 210 - 230 | Flexible; overheating damages material |

How to Heat the Nozzle Properly

- Use the printer's screen or computer program to set the right temperature.

- Wait for the nozzle to reach that temperature and stay there. Then you can do the next step.

- Don't set the temperature too high, because it can burn the plastic and damage the nozzle.

Heating the nozzle the right way makes it easier to take the plastic out. It also stops the plastic from breaking or getting stuck inside. Preventing issues like this is a core part of maintenance, but you can find solutions for 14 common 3D printing problems if they do occur.

Using Printer Controls and Manual Techniques to Unload Filament Safely

You should first stop the print and then use the printer's "unload" button. The machine pulls the plastic out gently, so it doesn't damage any parts.

How to Do It

- First, stop the current print job. This is so the printer stops pushing plastic out.

- Next, go to the printer's menu and choose the "Unload" or "Retract" option.

- Finally, let the printer finish the whole process. Don't touch anything until it's done.

When Manual Assistance Is Needed

Sometimes, the automatic unloading won't fully remove the filament. In such cases:

- Gently pull the filament out by hand.

- If you meet resistance, pause and reheat the nozzle before trying again.

- Pull slowly and steadily—applying too much force can cause the filament to snap or damage the extruder.

Employing these careful steps protects your printer components and helps avoid costly repairs.

Avoiding Breakage and Blockages

How quickly and forcefully you remove the filament matters. Rushing or pulling hard increases the chance of breakage or nozzle clogging.

- Always retract filament at a slow, steady pace.

- Watch the filament closely as it leaves the nozzle to catch any signs of snapping.

- Use proper cleaning tools to remove any residual plastic from the nozzle tip once unloading finishes.

Maintaining a clean nozzle is essential to prevent buildup and prepare your printer for the next filament load.

Post Unloading Checklist to Ensure Printer Readiness

After filament removal, perform these quick checks:

- Visually examine the nozzle tip for leftover filament and clear it with a needle or brush if needed.

- Conduct a test extrusion or "cold pull" to confirm smooth filament flow.

- Inspect filament guide tubes and extruder gears for any trapped bits or wear.

These steps help avoid print failures and keep your machine in good working order.

Common Issues During Unloading and How to Fix Them

Here are those instructions rewritten with simpler words and basic connections.

If the Plastic Gets Stuck

If the plastic gets stuck when you unload it, don't pull it hard. First, stop. Then, heat the nozzle again so the plastic gets soft, and try the "unload" button again. You can also try to wiggle the plastic back and forth a little bit while you pull it out slowly. If it's really stuck, you might have to take off the nozzle and clean it well.

When to Clean the Nozzle

You need to clean the nozzle if it gets stuck a lot or if the plastic comes out unevenly. It also needs cleaning if the plastic breaks when you take it out. If your prints suddenly start to look bad, that's a big sign. You should also look at the nozzle tip for old, burnt plastic.

If the Plastic Breaks Inside

If the plastic breaks when you pull it out, first carefully take out the broken pieces from the feeder and the tube. Then, heat the nozzle again so the stuck bits get soft. After that, clean the nozzle with the right tools, and then try to take the rest out slowly.

Cleaning and Maintaining the Nozzle and Bowden Tube

Regular cleaning extends the lifespan of your printer and improves print consistency.

Tips for Nozzle Cleaning

- Use fine needles or dedicated brushes to clear away residual filament.

- When necessary, perform a cold pull with a soft filament to remove stubborn blockages.

- Avoid abrasive tools that could damage the nozzle's surface.

Bowden Tube Maintenance Schedule

| Task | Description | Frequency |

| Inspect for wear | Check for cracks or blockages | Every 3 months |

| Clean inner walls | Use cleaning filament or soft brushes | Monthly |

| Replace tubes | Swap out damaged tubes | As needed |

Routine upkeep prevents unexpected downtime and ensures smooth filament feeding. However, it's important to note that maintenance schedules are often better based on usage rather than a fixed calendar; check for wear based on print volume and clean as needed.

Proper Filament Storage to Avoid Moisture Damage

Once unloaded, filaments must be stored carefully to prevent moisture absorption, which negatively affects print quality and mechanical properties.

Why Moisture Matters

Some plastics, like nylon and TPU, soak up water right from the air. This is a big problem for 3D printing. When you print with this wet plastic, the water inside boils and turns into steam. This steam causes problems:

- It makes bubbles and hissing sounds.

- The layers don't stick together well, so the print is weak.

- The outside of the print looks ugly and rough.

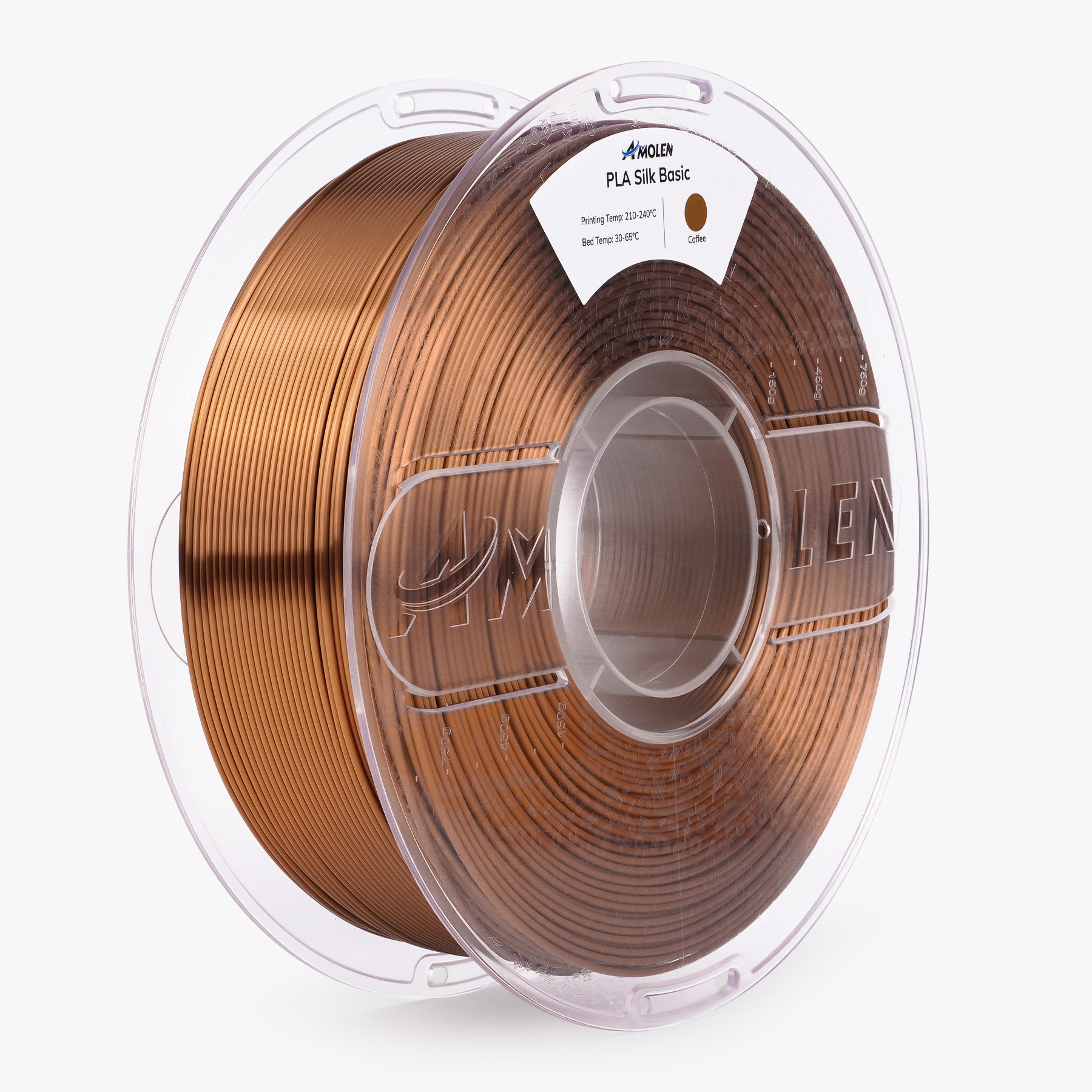

The water also damages the plastic itself, so your finished prints might be very easy to break or have lots of thin, spiderweb-like strings on them. Even aesthetic materials like our Silk PLA filaments perform best when kept dry to preserve their unique finish.

Effective Methods for Drying Filaments

- DIY drying boxes: Seal your filament with desiccants in an airtight container, adding a low-wattage heat source to maintain around 40–50°C.

- Household ovens: Use with caution; keep the temperature low (~50°C) and monitor constantly to prevent melting.

- Commercial filament dryers: Designed for controlled, safe drying with humidity sensors.

Depending on moisture levels, dry filaments for several hours up to overnight. Avoid overheating to prevent deformation or softening. After drying, immediately store filaments in sealed bags with desiccants.

Take Care of Your Filament for Better Prints

To take out plastic the right way, you need to heat the nozzle correctly, use the printer's buttons carefully, and help the plastic out gently if it gets stuck. After you unload, it's a good idea to check your printer's parts and keep them clean. This is so you don't get jams or bad prints later. You should also store your plastic the right way by keeping it dry. This keeps the plastic in good shape and saves you time and money. If you do all these things, your printer will work well, and your prints will always look great. Following a comprehensive PLA filament printing guide can reinforce these habits and lead to consistent success.